- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

Manufacturer-independent machine connection

Modular, scalable and independent process control system.

The JMS 4.0 is modular, scalable and independent of manufacturing processes. Thanks to interfaces to all common machine control systems, machine tools from a wide range of manufacturers and generations can be integrated. This gives you a free choice of manufacturer and machine type.

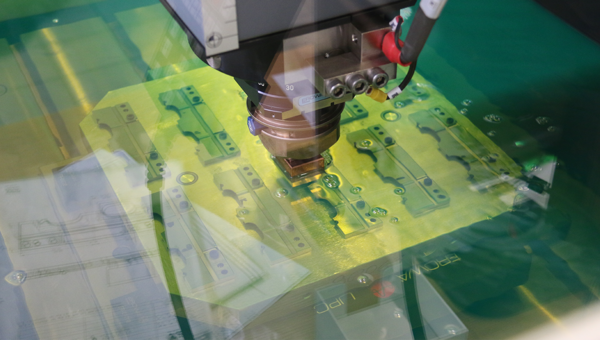

Milling

Efficient milling of workpieces and electrodes. JMS 4.0 handles the assignment and transfer of NC programmes fully automatically.

The integrated tool management shows the operator the current availability of the tools and their service life at all times.

Die-sinking EDM

Transfer existing technology data from CAD/CAM systems and integrate it into the process: Web-based plug-ins fully integrate your CAD system into JMS 4.0.

JMS 4.0 manages both workpieces and electrodes and takes over the automatic sequence control of the die-sinking EDM process.

Wire cutting WEDM

The steps that are important for wire cutting, such as cleaning and drying the workpieces (to prevent corrosion) in the automated system, are mapped, as is the manual fixing of the workpieces between the main cut and the separating cut.

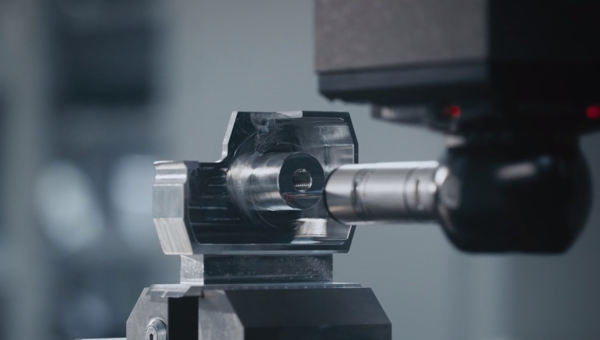

Measuring

Determining offset data and zero points as well as fully automated measurement of workpieces and electrodes is central to every production process.

Thanks to the full integration of coordinate measuring machines, JMS 4.0 provides you with all the necessary functions from pre-setting to final inspection.

Grinding

JMS 4.0 supports both surface and jig grinding. The grinding programmes are managed by the system and loaded and executed on the machine at the right time.

The automated changing of grinding tools and their management is also handled by JMS 4.0.

Cleaning

In fully automated processes, it is necessary to clean and dry the workpieces before measuring, for example. Full integration of various cleaning technologies has been realised in JMS 4.0.

Additive manufacturing

State-of-the-art technologies, such as additive manufacturing, are an integral part of our system and can be seamlessly integrated.