- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

NEW Automation Solution

Smart automation for all manufacturing technologies with the EROWA Robot Compact 150

NEW Automation Solution

Smart automation for all manufacturing technologies with the EROWA Robot Compact 150

Highest productivity, flexibility and process reliability are more important than ever in today's world. Thanks to our products from the «Flexible Manufacturing Concept» all ways are open to you to maximize your production step by step and to increase your competitiveness.

Modular EROWA solutions increase the output and flexibility of your machine tool. Our scalable automation solutions accelerate the workflow and optimize process reliability. Thanks to our 50 years of experience, Industry 4.0 is firmly anchored in our DNA and thus a part of us.

The EROWA general catalogue provides a comprehensive overview of our versatile product range and innovative solutions. From precision clamping systems and automation solutions to process control systems - here you will find everything you need for efficient manufacturing processes. Our catalogue shows how we support demanding industries such as medical technology, aerospace and precision manufacturing, always focusing on productivity, flexibility and quality. Discover how EROWA is shaping the production of the future!

Our innovative products and solutions are driving advancements across exciting industries like medical technology, aerospace, automotive, and beyond. What sets us apart is our team of engaged and forward-thinking employees. Together, we tackle challenges head-on, foster innovation, and push the boundaries of what’s possible in manufacturing and automation.

Cookie settings

We use cookies to provide you with an optimal user experience. Some cookies are necessary for the operation of the site, others are used for statistical purposes, comfort settings, or to display personalized content. You can decide yourself which cookies you want to allow. Please note that due to your settings, not all functionalities of the site may be available. For more information, please refer to our Privacy Policy and Cookie Policy. Show details

Required

These cookies are mandatory to operate the website and to enable security functions. They also allow you to remain comfortably logged in to your profile for further visits to our website.

Statistics

We collect anonymous data for statistics and analyses that help us to constantly optimise our website and its contents.

Production- and Precision Mechanics

Tool and Die

making

Production- and Precision Mechanics (PPM)

Tool and Die

making (EDM)

PPM < Production- and Precision Mechanics

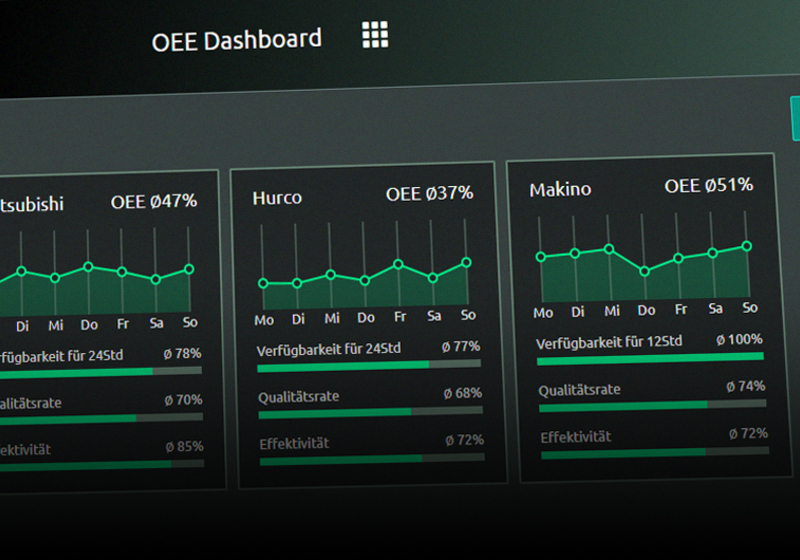

Smart Factory Central Command

Planning, controlling and monitoring of the integrated manufacturing process

The EROWA process control system JMS 4.0 connects all data and controls the entire production process. It automates the data flow from ERP and CAD/CAM to the production cells. JMS 4.0 takes charge of the control of the robots as well as the data transfer and control of the connected machines. In short: with EROWA JMS 4.0 you have the entire workflow well in hand before, during and after processing your orders.

Learn more about JMS 4.0 Explanation VideoMore Info

PPM < Production- and Precision Mechanics

Setup parallel to machining for more spindle time

Central set-up of workpieces and tools

Machine tools only generate profit when they produce. Increasing productivity starts with EROWA clamping systems and eliminating machine downtime. Workpieces are set up and palletised outside the machine while it is still producing. The workpiece change on the machine is carried out in seconds, powerfully, µ-accurately and without loss of the zero point.

EROWA Tooling SystemsMore Info

PPM < Production- and Precision Mechanics

Entry-level solutions in monoblock design

Single machine automation for transfer weights up to 300 kg

Simple single machine loading is the motto of our Robot Easy series. The robust monoblock design guarantees fast commissioning, so that palletised workpieces from 1kg to 300kg make their way onto your machine table in no time at all. The many configuration options are geared to your range of applications and offer a fast return on investment with these entry-level solutions.

Learn moreMore Info

PPM < Production- and Precision Mechanics

Minimal footprint - Maximum spindle-runtime

Twin machine monoblock automation up to 120 kg

The answer to the requirement of combining high autonomy with the smallest possible unit size. Added to this is fast commissioning in connection with the loading of up to two machine tools. An integrated, stable loading station with a clear operating panel ensures ergonomic changeover of unmachined parts and machined workpieces.

Learn moreMore Info

PPM < Production- and Precision Mechanics

6 axes for all transferweights

The customised solution for workpiece, blank and tool handling

EROWA 6-axis solutions offer maximum latitude in all available dimensions: Palletised workpieces, raw parts, semi-finished products and even tools from 1 to 1,000kg may be loaded on up to 20 machines. Our solutions use standardised components from our proven EROWA modular system and are precisely aligned to your production order.

Learn moreMore Info

PPM < Production- and Precision Mechanics

Large dimensions - heavy workpieces

Multi-machine automation of workpieces or machine tables up to 4 tons

Masterful loading of heavyweights - or simply say "EROWA LoadMaster". The machine design quality of the highest standard in combination with the space-saving storage location with up to four magazine levels is unparalleled. Palletised workpieces or even entire machine tables of up to four metric tons are efficiently loaded, which significantly reduces the chip-to-chip time between jobs. The ergonomic loading station and the scalable process control system ensure optimum operator comfort.

Learn moreMore Info

PPM < Production- and Precision Mechanics

Strong automation up to 500kg

Modular rail solution for multiple machines and different machining methods

The devices of the Robot Dynamic family offer plenty of payload capacity to automate jobs from batch size one efficiently and across several process steps. Workpiece handling of various sizes from zero to 500 kg in 15 seconds? No problem for the Robot Dynamic. That's how fast the gripper change is to reliably transport even the heaviest pallets. The modularity allows the entire system to be expanded at a later date to handle additional machines. Uncompromisingly tailored to the needs of Industry 4.0, the EROWA process control system JMS 4.0 takes care of job management. This ensures that the correct job is produced efficiently at the right time on the appropriate machine.

Learn moreMore Info

PPM < Production- and Precision Mechanics

24/7 workpiece and tool transport

Automated transfers between robotic cells throughout the production area

New perspectives in complete workshop automation with the EROWA JMS 4.0 process control system and shop-floor transport via AGV technology. Workpieces, electrodes and tools are transported from central set-up stations across the entire production area to the manufacturing cells. EROWA assumes the central management of the cross-technology linking. With standardised hardware and the proven JMS 4.0 process control system, this ensures efficient work organisation and cost-optimised production processes across a wide range of manufacturing technologies.

Learn moreMore Info

EDM < Tool and Die

making

Smart Factory Central Command

Planning, controlling and monitoring of the integrated manufacturing process

The EROWA process control system JMS 4.0 connects all data and controls the entire production process. It automates the data flow from ERP and CAD/CAM to the production cells. JMS 4.0 takes charge of the control of the robots as well as the data transfer and control of the connected machines. In short: with EROWA JMS 4.0 you have the entire workflow well in hand before, during and after processing your orders.

Learn more Explanation VideoMore Info

EDM < Tool and Die

making

Setup parallel to machining for more spindle time

Central set-up of workpieces and tools

Machine tools only generate profit when they produce. Increasing productivity starts with EROWA clamping systems and eliminating machine downtime. Workpieces are set up and palletised outside the machine while it is still producing. The workpiece change on the machine is carried out in seconds, powerfully, µ-accurately and without loss of the zero point.

Learn moreMore Info

EDM < Tool and Die

making

24/7 workpiece and tool transport

Automated transfers between robotic cells throughout the production area

New perspectives in complete workshop automation with the EROWA JMS 4.0 process control system and shop-floor transport via AGV technology. Workpieces, electrodes and tools are transported from central set-up stations across the entire production area to the manufacturing cells. EROWA assumes the central management of the cross-technology linking. With standardised hardware and the proven JMS 4.0 process control system, this ensures efficient work organisation and cost-optimised production processes across a wide range of manufacturing technologies.

Learn moreMore Info

EDM < Tool and Die

making

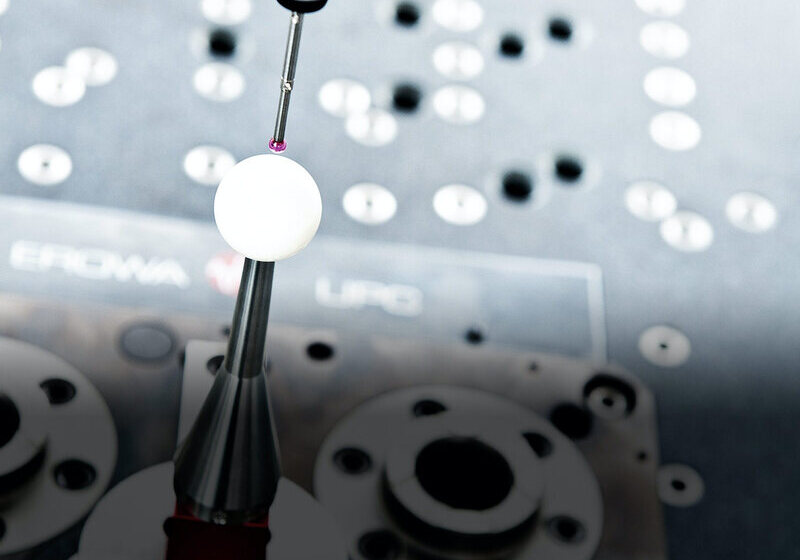

Reference point definition outside the machine

Efficiently determine workpiece zero point and electrode offset data

Zero point determination is an important step in the production of workpieces and electrodes. Often this is done in the machine tool. However, this takes up valuable time during which the machine is not productive. With the help of EROWA PreSetting devices and the workholding systems, this is done outside the machine. The determined offset values are transmitted digitally to the machine: quickly, efficiently and without the risk of typos.

Learn moreMore Info

EDM < Tool and Die

making

Efficient electrode and workpiece production

Single or twin machine monoblock automation for electrode production

Robots in monoblock design guarantee fast, straightforward commissioning, so that chips start flying on your machine within a very short time. The integrated loading station and the intuitive control ensure ergonomic operation. Ample magazine spaces with a high capacity ensure sufficient autonomy until late in the day and even beyond.

Learn moreMore Info

EDM < Tool and Die

making

Taking EDM to a new level

Single or twin machine monoblock automation for EDM

Up to 369 electrodes on two square metres speak for themselves regarding high autonomy in automated EDM. Fully configurable magazines leave nothing to be desired in the use of different pallet sizes, even in the mixed operation of electrodes and workpieces. The JMS 4.0 process control system manages the entire data flow so that the proper workpiece with the corresponding electrodes and offset data, including the NC programme, ends up on the EDM machine.

Learn moreMore Info

EDM < Tool and Die

making

6-axis automation for any application

Flexible 6-axis automation for any transfer weight

Maximum latitude in all dimensions combined with a minimal footprint - the credo of Robot Six automation solutions. Ingenious kinematics combined with EROWA standard components result in a modular system that is always suitable for your production job. With the integrated gripper change, electrodes as well as palletised workpieces of various sizes are reliably loaded onto the machine table or directly into the quill. If required, AGV units will transport electrodes or workpieces to or from the automation cell.

Learn moreMore Info

EDM < Tool and Die

making

Maximum efficiency and flexibility across the entire process chain

Modular multi-machine rail solution for different machining methods

When it comes to the automation of complete process chains, the linear solutions of the Robot Dynamic range are uncompromisingly tailored to the requirements of Industry 4.0. This means more autonomy and thus more spindle time across several machines into the late evening or morning hours. Data and job management is handled by the EROWA JMS 4.0 process control system and offers the user an intuitive user interface. The modular concept of the Robot Dynamic covers any needs in order alignment and remains extendable for later expansions.

Learn moreMore Info