- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

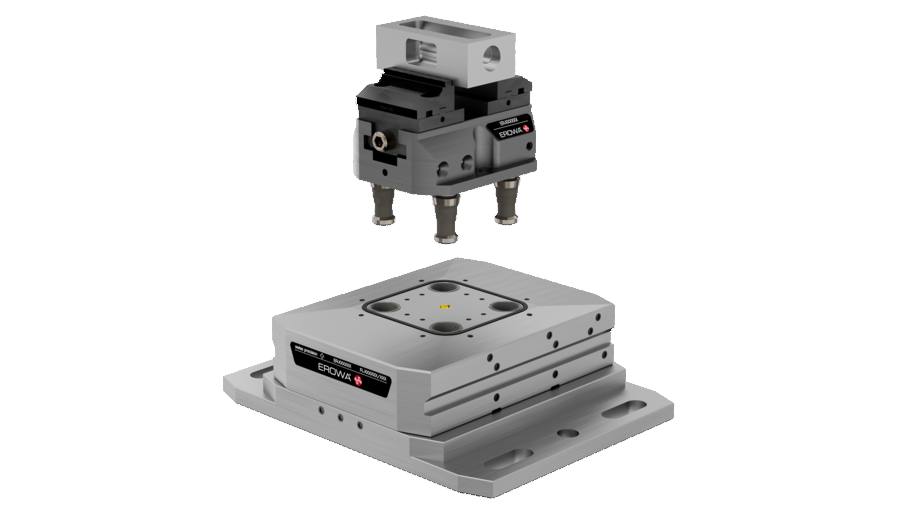

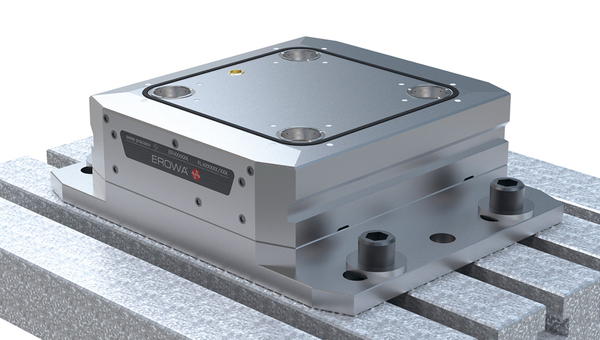

EROWA VPC

Process-reliable automation of vises

The EROWA VPC (Vise Power Clamp) Clamping System guarantees powerful, and precise clamping of vises, fixtures and workpieces with pitch dimensions 52 & 96 mm.

The two VPC chuck sizes with the matching VPC clamping spigots form the core. The universal application possibilities open up the greatest flexibility in workpiece production. With the matching EROWA handling device, automated in a process-safe manner, you increase productivity massively.

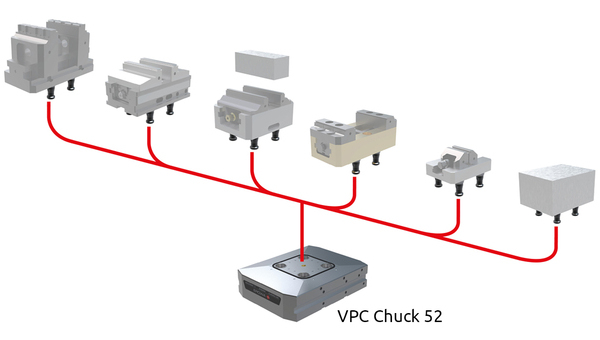

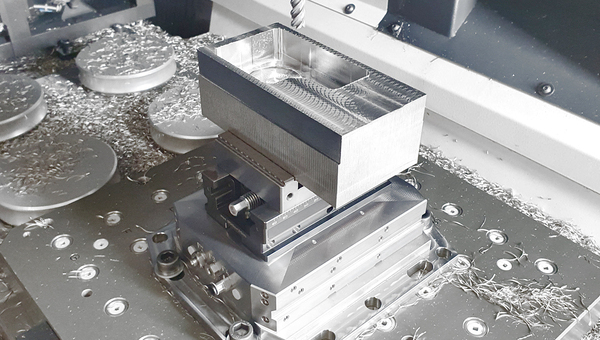

VPC is clamping everything

All workpiece vises available on the market with a 52 mm or 96 mm pitch can be quickly and precisely accommodated in the EROWA VPC clamping system.

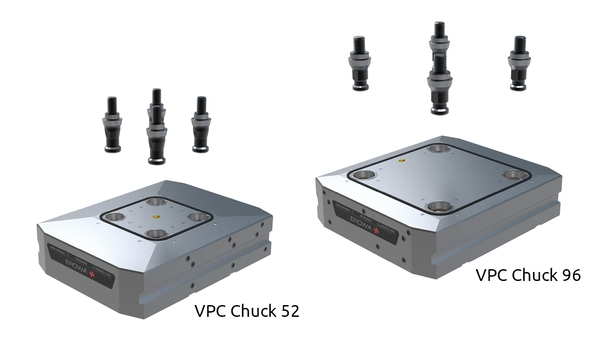

Choose from two system sizes

There are two system sizes of EROWA VPC:

• VPC 52 chuck & clamping spigot for pitch 52 mm

• VPC 96 chuck & clamping spigot for pitch 96 mm

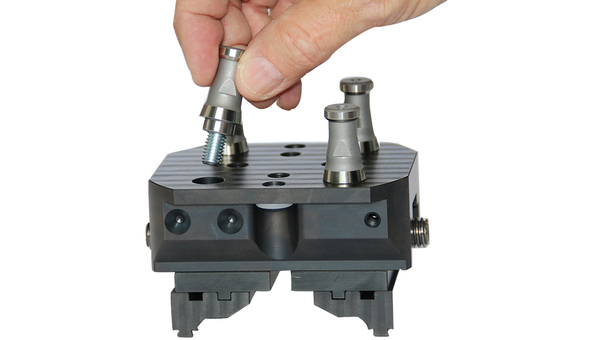

Simple and quick preparation

Preparation of vises, fixtures and workpieces is simple: Screw in VPC clamping spigots 52 or 96 and tighten – done!

Performance and precision

The proven, functional & sophisticated clamping technology of the VPC includes an integrated Z-support cleaning, status monitoring and integrated sealing.

VPC chucks can be mounted directly or via a base plate on the machine table.

Powerful and precise

With a clamping force of 15 kN (reclamped), the workpiece clamps or workpieces are clamped powerfully and precisely in the VPC chuck.

The workpiece carrier change takes place in seconds with a repetition accuracy < 0.003 mm.

Process-reliable clamping / trouble-free automation

The VPC clamping spigots are made of high-quality and hardened steel and offer a long lifespan. The ground functional surfaces ensure optimized insertion behavior in the VPC chuck.

This ensures process-reliable clamping and trouble-free automation.

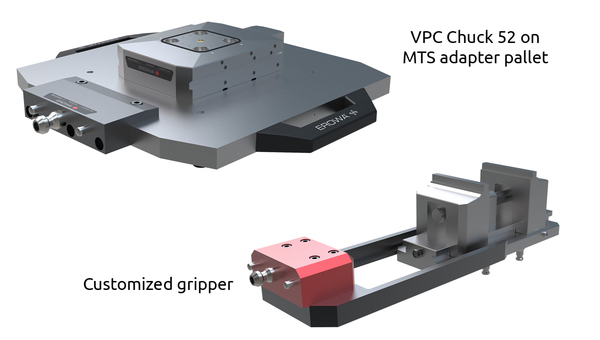

Maximizing of manufacturing flexibility

It is possible to adapt different system sizes with each other. This maximises manufacturing flexibility. With adapter pallets, the VPC tooling system can be flexibly integrated into the EROWA UPC (picture) and MTS systems.

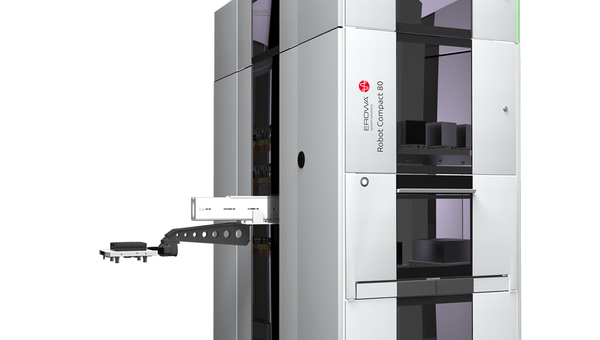

Automation options

Automated loading significantly increases productive hours on your machine tool. EROWA offers the right automation option depending on your needs. We will be happy to advise you on your individual VPC automation solution.

According to your request

EROWA UPC and MTS adapter pallets can be operated with standard grippers.

If you need an individual gripper according to your requirements: No problem. We will be happy to develop a suitable solution for you.