- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

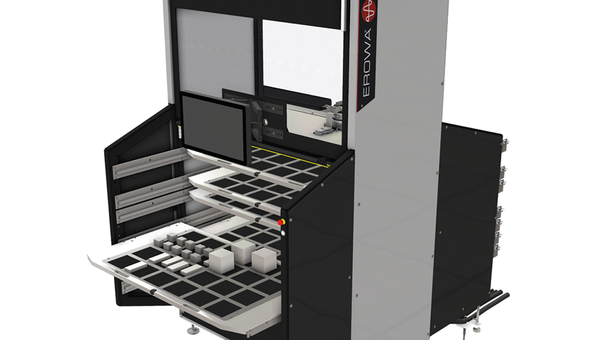

EROWA Robot Six Mixed Handling System

Maximum flexibility with minimum effort

The targeted expansion of the EROWA Robot Six with a drawer magazine and automatic clamping station for parts and pallet handling makes it a highly flexible mixed handling system.

This allows you to automate a wide variety of processes with just one system, saving valuable floor space and time.

Plenty of space

With up to nine drawers, the drawer magazine can be freely configured to the sizes of the parts to be processed and offers a large work supply for bridging unmanned shifts or production over the weekend.

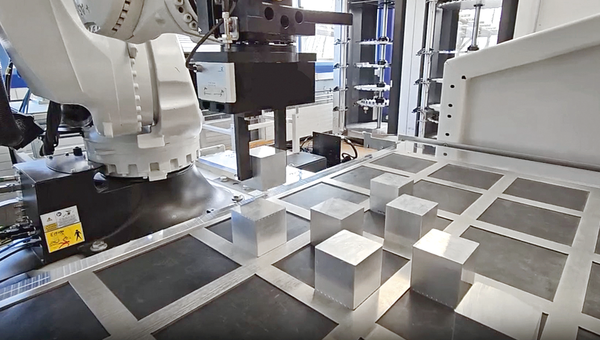

Freely configurable

The individual configuration of the drawer grid allows application-specific grid plates for raw parts or mold cavities for semi-finished parts to be integrated as required. Individual grids for each drawer create space for a wide range of workpieces – while maximizing capacity utilization.

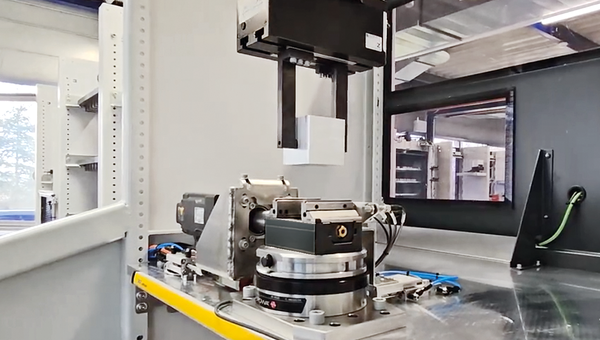

Everything Under Control

The gripper system is equipped with an EROWA standard coupling for picking up any interchangeable grippers for pallet handling, a servo gripper for raw parts/semi-finished parts, and a drawer opener. A nozzle for blowing away chips and cooling lubricants can also be integrated as an option.

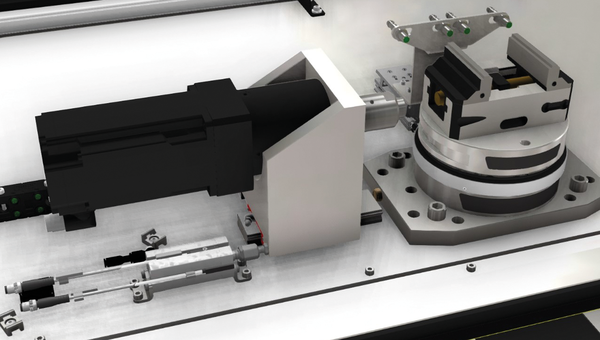

Clamping station

The clamping station can be individually configured depending on the model of the self centering vise used. Thanks to its scalability, the system can be expanded to include other types of self centering vises with different dimensions and clamping stations.

Securely Clamped

The gripper automatically adjusts to the size and geometry of the workpiece. After being removed from the drawer magazine, the workpiece is precisely inserted into the self centering vise in the clamping station and secured with the desired torque.

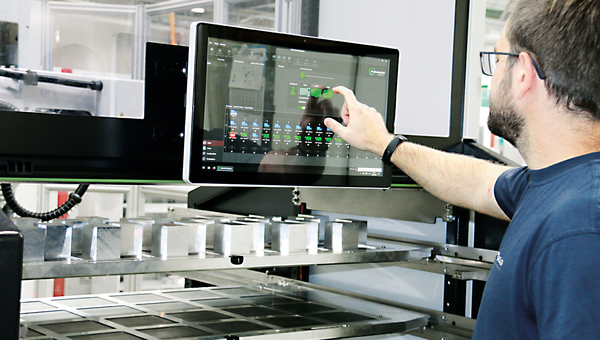

Everything at a Glance

Seamless integration into the EROWA JMS 4.0 ProductionLine control system - Intuitive operation through the integrated touch monitor, conveniently located on the drawer magazine.

Stay informed with real-time visibility of current drawer loads and automatic validation of space conflicts.